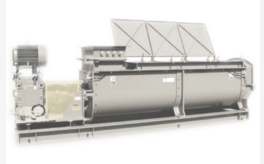

Double shaft mixer

MTS twin-shaft continuous mixer adopts the screw blades to make the material move forward alternately within the machine, which has the characteristics of strong mixing ability and continuous and even feeding. It is suitable for mixing and humidifying loose materials, such as coal humidification, and it can also be used as a pretreatment equipment for fine mixing.

■ Its continuity makes mixing in order.

■ The special designed shape of blades make it a efficient mixing. The blade arrangement angle along the axis is different, which is more conducive to the improvement of mixing accuracy.

■ The gentle mixing process does not break the material's initial status.

■ Blades are made with high abrasive resistance material, like hardfacing wear-resisting electrode, thermal spraying cermet and ceramic blade are available.

■ The transmission system uses twin-shaft reducer which is powered directly through universal joints, to achieve a pure torque input power.

■ When used for humidification, the special atomizing nozzle and liquid feeding system with adjustable flow rate can ensure uniform humidification of materials

Pin Mixer Granulator principle and structure:

■The pin shaft is ideal for applications requiring extreme micro-mixing granulation and small particle size control.

■The equipment is a cylindrical shape, a fixed shell, and the ratio of length and diameter is between four and five. The inner shell is a replaceable rubber gasket and a pair of spiral radial extension pins. The pin shaft has a reasonable and strict relationship with the inner wall.

■The speed of the rotor is higher than that of the traditional blade mixer. The raw material enters from one side of the equipment, and is discharged from the bottom of the other side. The liquid is added through the automatic system. When the equipment is running, the fine mixing and micro-agglomeration will take place. The final product is a wet, dense pellet.

MTS Twin-shaft Mixer Technical parameters:

■The pin shaft is ideal for applications requiring extreme micro-mixing granulation and small particle size control.

■The equipment is a cylindrical shape, a fixed shell, and the ratio of length and diameter is between four and five. The inner shell is a replaceable rubber gasket and a pair of spiral radial extension pins. The pin shaft has a reasonable and strict relationship with the inner wall.

■The speed of the rotor is higher than that of the traditional blade mixer. The raw material enters from one side of the equipment, and is discharged from the bottom of the other side. The liquid is added through the automatic system. When the equipment is running, the fine mixing and micro-agglomeration will take place. The final product is a wet, dense pellet.

MTS Twin-shaft Mixer Technical parameters:

Where there is briquette, mixing, drying,

and system solution related,there is Kaizheng

Copyright@2024 Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd