Grinding roller

In the process of high-pressure roller compaction and densification, a significant technological breakthrough is high-pressure grinding. This innovative technology is widely used in the cement and mineral processing industries. We encourage you to contact us for more technical information and methods to process your products.

Applied materials:

Cement clinker,Cement raw materials (limestone, clay),Slag,Titanium oxide,Minerals,Synthetic fibers

Process Description

Based on our experience in designing and manufacturing high-pressure extrusion roller equipment, we have developed a crushing device specifically suited for grinding and granulating. It can be used for grinding crushable materials and for the dissociation of non-crushable materials. When used for grinding, it produces a wide range of particle sizes in the output. The high-pressure roller press can be used independently or in combination with a ball mill, with the ultimate goal of reducing energy consumption and operating costs of the entire grinding process.

Based on our experience in designing and manufacturing high-pressure extrusion roller equipment, we have developed a crushing device specifically suited for grinding and granulating. It can be used for grinding crushable materials and for the dissociation of non-crushable materials. When used for grinding, it produces a wide range of particle sizes in the output. The high-pressure roller press can be used independently or in combination with a ball mill, with the ultimate goal of reducing energy consumption and operating costs of the entire grinding process.

Compared to traditional technologies, this method offers the following advantages:

■ 30% energy savings.

■ Increased yield of the final crushed product from 30% to 50%.

■ Significantly reduced installation, operation, and maintenance costs.

■ The roller press can be installed in a new plant or used for technical upgrades and modifications of existing

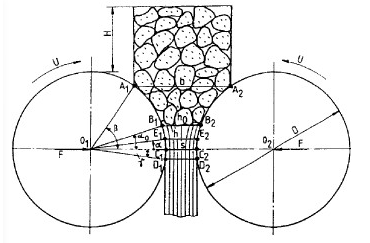

The main structure of a high-pressure roller press consists of a pair of counter-rotating rollers. One roller is fixed, while the other is a movable roller supported on the frame by a hydraulic system. The surface of the rollers is specially treated to ensure sufficient strength and wear resistance. When the material is continuously fed into the gap between the rollers, it is powerfully crushed. As the design basis for the compaction machine, it is crucial to consider the material characteristics and operating objectives. When the user is performing grinding, it is necessary to understand the particle size distribution and hardness of the material. When used for the dissociation of unbreakable materials, it is necessary to know the maximum particle size of the unbreakable materials.

Technical Features

The drive system has two configurations: for smaller models, it uses a motor-reducer-double output shaft synchronous gearbox with reduction gears-two pressure rollers; for larger models, it uses a dual motor-reducer-two pressure rollers. It features pure torque output. The material of the pressure roller sleeves is selected based on the material being processed and customer requirements. It can be a tungsten carbide stud structure or a hardfacing structure using wear-resistant materials.

Roller surface protection technology

Whether it's a briquetting machine, a compaction machine, or a high-pressure roller press, the main wear parts are the two compression rollers. The material and surface treatment of these rollers are therefore crucial.

■ For briquetting machines, we select bearing steel, tool steel, or stainless steel depending on the material being processed.

■ For compaction machines, the roller surface undergoes wear-resistant treatment and special surface profiling to improve its wear resistance and compaction capabilities.

■ For high-pressure roller presses, the roller surface utilizes a tungsten carbide stud structure or a wear-resistant overlay welding structure to enhance its wear resistance and crushing capabilities.

■ 30% energy savings.

■ Increased yield of the final crushed product from 30% to 50%.

■ Significantly reduced installation, operation, and maintenance costs.

■ The roller press can be installed in a new plant or used for technical upgrades and modifications of existing

The main structure of a high-pressure roller press consists of a pair of counter-rotating rollers. One roller is fixed, while the other is a movable roller supported on the frame by a hydraulic system. The surface of the rollers is specially treated to ensure sufficient strength and wear resistance. When the material is continuously fed into the gap between the rollers, it is powerfully crushed. As the design basis for the compaction machine, it is crucial to consider the material characteristics and operating objectives. When the user is performing grinding, it is necessary to understand the particle size distribution and hardness of the material. When used for the dissociation of unbreakable materials, it is necessary to know the maximum particle size of the unbreakable materials.

Technical Features

The drive system has two configurations: for smaller models, it uses a motor-reducer-double output shaft synchronous gearbox with reduction gears-two pressure rollers; for larger models, it uses a dual motor-reducer-two pressure rollers. It features pure torque output. The material of the pressure roller sleeves is selected based on the material being processed and customer requirements. It can be a tungsten carbide stud structure or a hardfacing structure using wear-resistant materials.

Roller surface protection technology

Whether it's a briquetting machine, a compaction machine, or a high-pressure roller press, the main wear parts are the two compression rollers. The material and surface treatment of these rollers are therefore crucial.

■ For briquetting machines, we select bearing steel, tool steel, or stainless steel depending on the material being processed.

■ For compaction machines, the roller surface undergoes wear-resistant treatment and special surface profiling to improve its wear resistance and compaction capabilities.

■ For high-pressure roller presses, the roller surface utilizes a tungsten carbide stud structure or a wear-resistant overlay welding structure to enhance its wear resistance and crushing capabilities.

Technical parameters:

Where there is briquette, mixing, drying,

and system solution related,there is Kaizheng

Copyright@2024 Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd