System solution -Direct Reduced Iron with Rotary Hearth Furnace (RHF)

Direct reduced iron with Rotary hearth furnace (RHF)

Basic introduction

The RHF process belongs to the coal-based direct reduction iron process and can be used to treat various iron-containing materials, such as (Magnetite, hematite, limonite) concentrate powder, metallurgical dust residue, -5mm oxidized pellets, DRI sludge, Mill scale, etc.

It mainly consists of the following areas

■ Dosing Area

■ Raw material Briquetting and drying Area

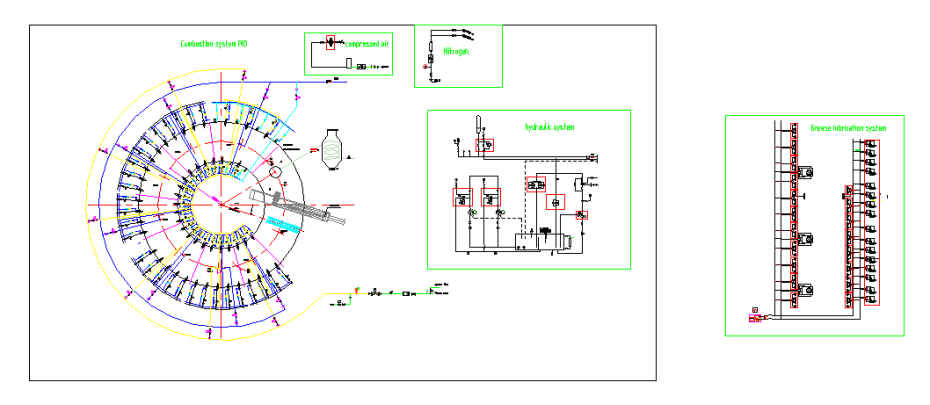

■ RHF Area

■ Cooling area

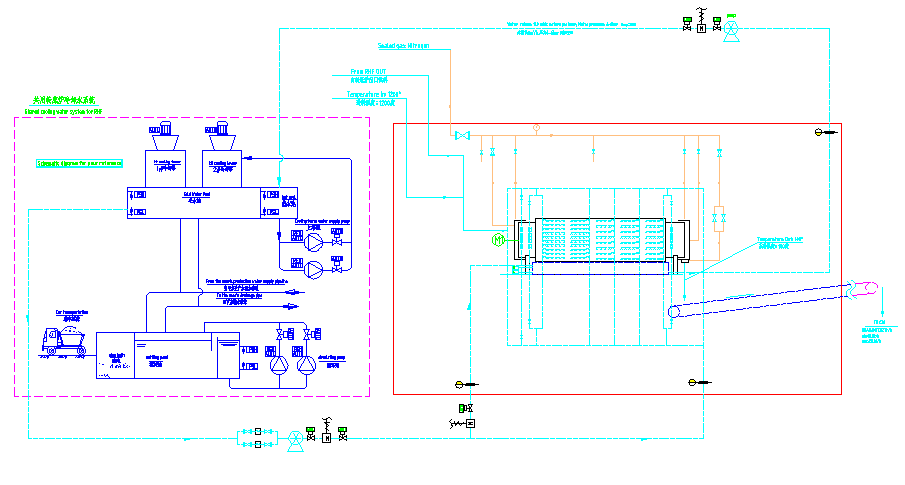

■ Water treatment system

■ Exhaust gas management system

■Automated control system

For the RHF system, metalized pellets with a MFe content of at least 80% can generally be obtained. If it is necessary to further increase the MFe content to above 90%, the following areas will be required for additional processing.

■Magnetic separation and CBI system

Advantages and Disadvantages of the RHF Process

Advantages

■The process is simple, with a short production line

■Fast direct reduction speed

■Low investment.

■High degree of automation, environmentally friendly.

■The key point is: it can handle materials that are difficult to pellet, such as -5mm oxidized pellets, Mill scale etc.

Disadvantages

The relatively low content of MFe in the product

Capacity of a single production line

Based on the raw materials :

100000ton/year ; 200000ton/year ; 300000ton/year ;

Based on the Finished product

≈60000ton/year ; ≈120000ton/year ; ≈180000ton/year

Advantages

■The process is simple, with a short production line

■Fast direct reduction speed

■Low investment.

■High degree of automation, environmentally friendly.

■The key point is: it can handle materials that are difficult to pellet, such as -5mm oxidized pellets, Mill scale etc.

Disadvantages

The relatively low content of MFe in the product

Capacity of a single production line

Based on the raw materials :

100000ton/year ; 200000ton/year ; 300000ton/year ;

Based on the Finished product

≈60000ton/year ; ≈120000ton/year ; ≈180000ton/year

Project implementation process

Where there is briquette, mixing, drying,

and system solution related,there is Kaizheng

Copyright@2024 Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd