Pin mixer

Pin mixer is used for micro mixing and granulation with suitable materials. Mixing and granulation are done in the same unit. Powder and liquid materials are converted into small pellets by means of high-speed rotors and pin shafts.

According to user's requirements and operating conditions, this series of equipment has a variety of configurations. Model MP--is the continuous operation mixing granulator, and model MPJ- is the intermittent operation mixing granulator. Compared with the continuous mixing granulator, the product qualification rate of intermittent operation equipment is higher, reaching more than 70%, but the single-machine processing capacity is lower.

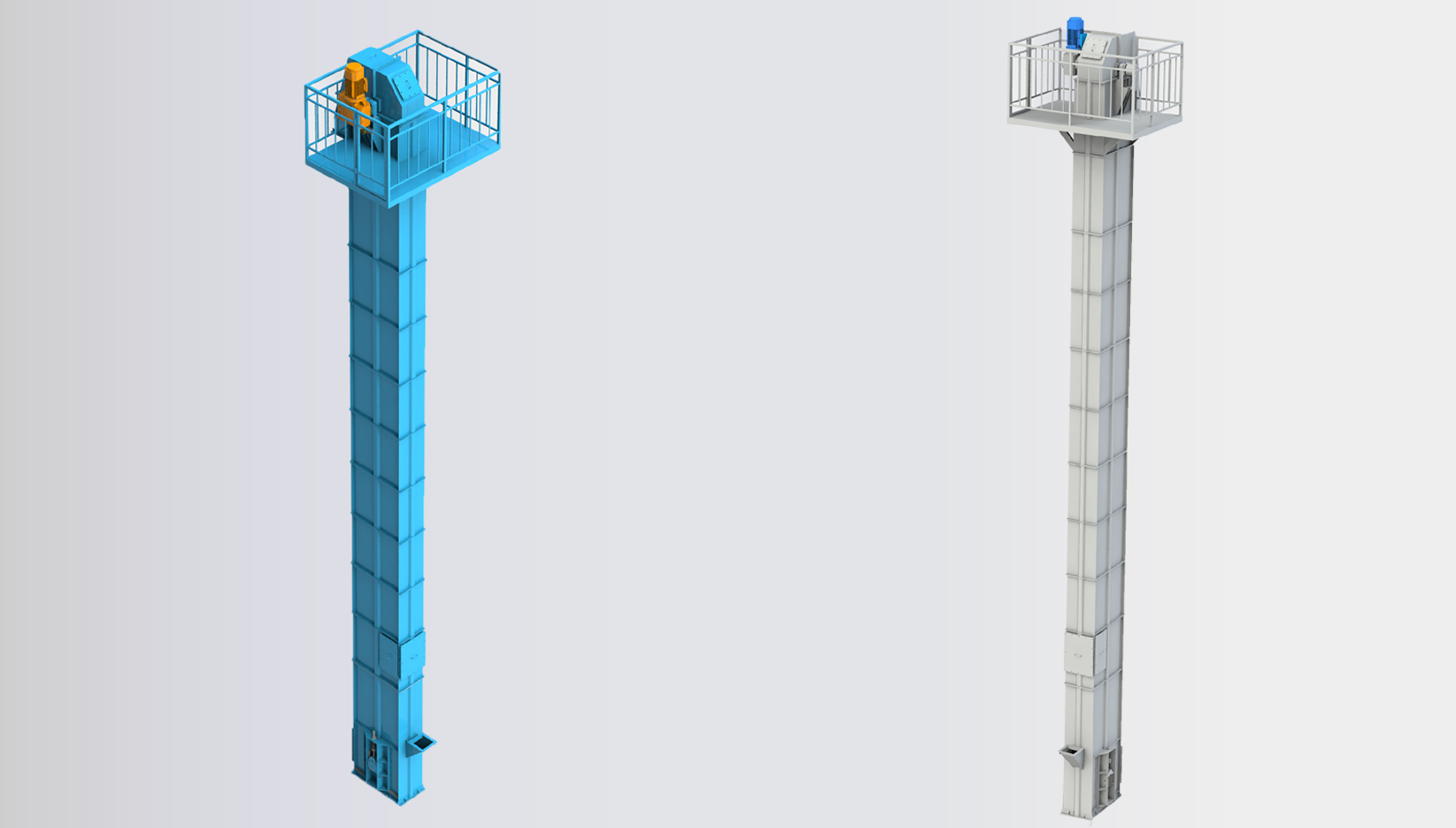

Pin Mixer Granulator principle and structure:

■The pin shaft is ideal for applications requiring extreme micro-mixing granulation and small particle size control.

■The equipment is a cylindrical shape, a fixed shell, and the ratio of length and diameter is between four and five. The inner shell is a replaceable rubber gasket and a pair of spiral radial extension pins. The pin shaft has a reasonable and strict relationship with the inner wall.

■The speed of the rotor is higher than that of the traditional blade mixer. The raw material enters from one side of the equipment, and is discharged from the bottom of the other side. The liquid is added through the automatic system. When the equipment is running, the fine mixing and micro-agglomeration will take place. The final product is a wet, dense pellet.

Pin Mixer Granulator Technical parameters:

Note: The profile of batch mixing granulating equipment can be requested from our company. Due to the different materials have various granulating time, there is no unique corresponding relationship between equipment specifications and production capacity.

■The pin shaft is ideal for applications requiring extreme micro-mixing granulation and small particle size control.

■The equipment is a cylindrical shape, a fixed shell, and the ratio of length and diameter is between four and five. The inner shell is a replaceable rubber gasket and a pair of spiral radial extension pins. The pin shaft has a reasonable and strict relationship with the inner wall.

■The speed of the rotor is higher than that of the traditional blade mixer. The raw material enters from one side of the equipment, and is discharged from the bottom of the other side. The liquid is added through the automatic system. When the equipment is running, the fine mixing and micro-agglomeration will take place. The final product is a wet, dense pellet.

Pin Mixer Granulator Technical parameters:

Note: The profile of batch mixing granulating equipment can be requested from our company. Due to the different materials have various granulating time, there is no unique corresponding relationship between equipment specifications and production capacity.

Where there is briquette, mixing, drying,

and system solution related,there is Kaizheng

Copyright@2024 Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd