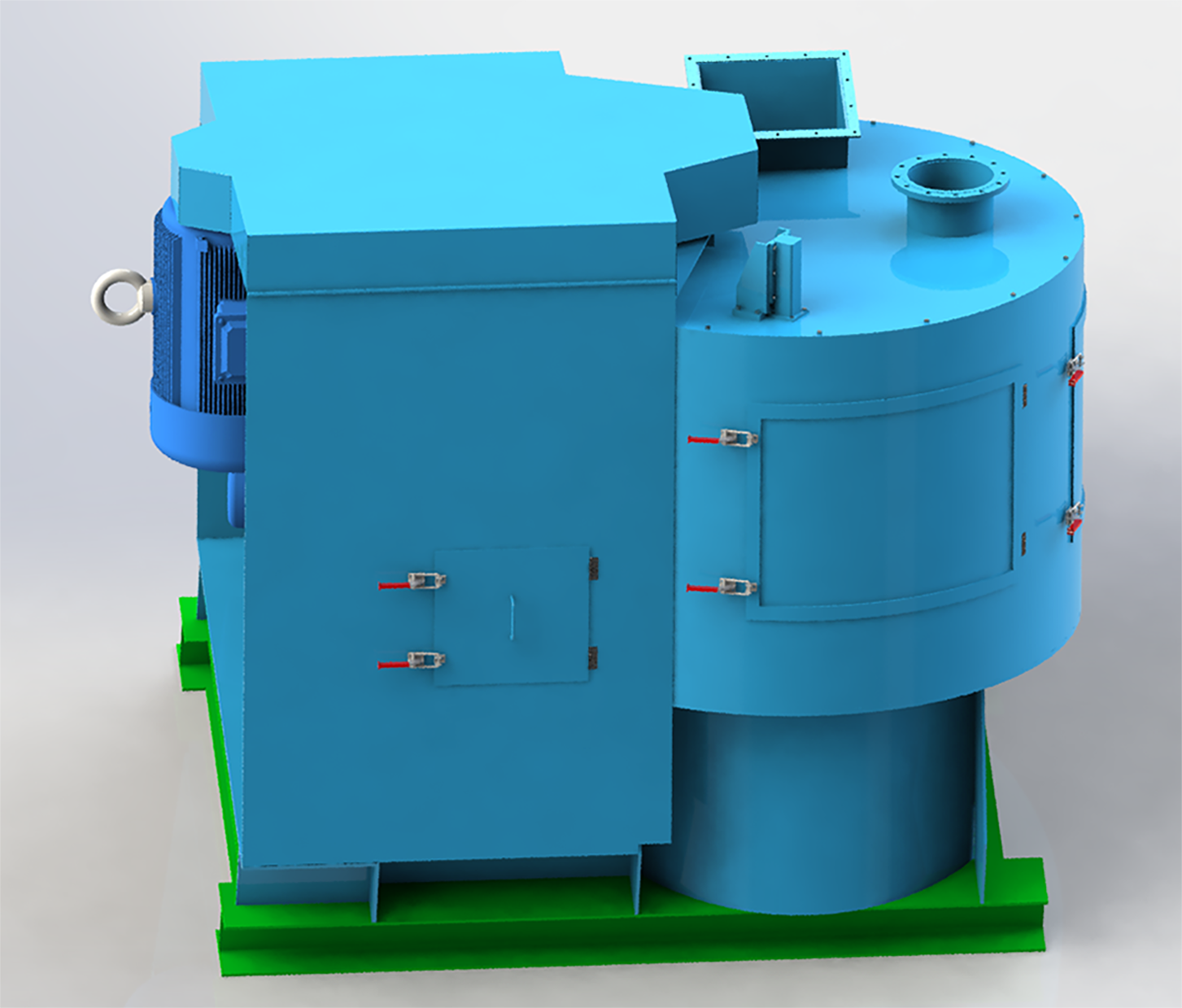

Ultra Pressure Briquette Machine

In practice, some materials are difficult to form and no binders are allowed to be added, which requires a ball press with a higher line pressure ratio. Generally, we consider a ball press with a line pressure ratio exceeding 20t/cm to be an ultra-high pressure ball press.

key word:

Category:

Briquetting machine

Flipping machine

Flipping machine Vertical

Vertical  Horizontal

Horizontal