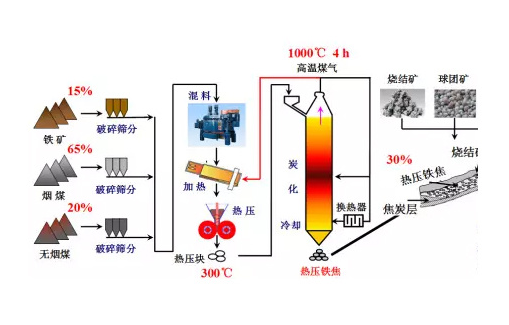

Composite iron coke complete set system

System introduction

Iron coke is a new type of low carbon iron-making charge, which has many advantages, such as the use of iron coke in blast furnace can reduce the temperature of heat reserve zone, improve smelting efficiency, reduce the coke ratio, and reduce the composition of CO2 emission system. Our company signed a cooperation framework agreement with Northeastern University, Anshan Thermal Energy Institute of China Steel, and Hesteel Steel Research Institute, and built a verification line for the verification and promotion of iron coke system technology.

System composition

The core of a typical sponge iron hot press block system includes a high-pressure hot press block machine, separation equipment, return material equipment, and conveying cooling equipment. In addition, there are cooling systems, dust removal systems, circulating water systems, etc.

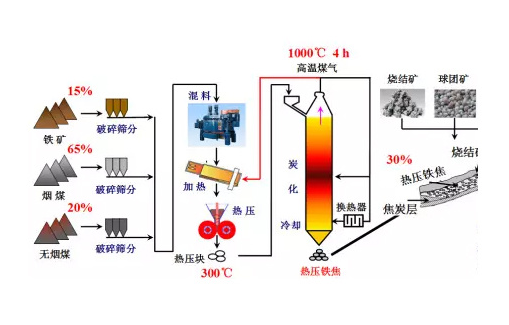

Technical advantages

The core equipment of this system, the high-pressure hot press block machine, is our company's patented technology.

The separation equipment can ensure the separation of adhesive hot press blocks and avoid unnecessary over crushing of materials.

The transport cooling system adopts new technology to fully utilize the latent heat of cooling water, thereby reducing the consumption of cooling water.

Application Fields/Materials

Directly reduce iron/sponge iron.