Medium Pressure Briquette Machine

Brand : KAIZHENG

Product origin : CHINA

Delivery time : To be confirmed

Supply capacity : Sufficient

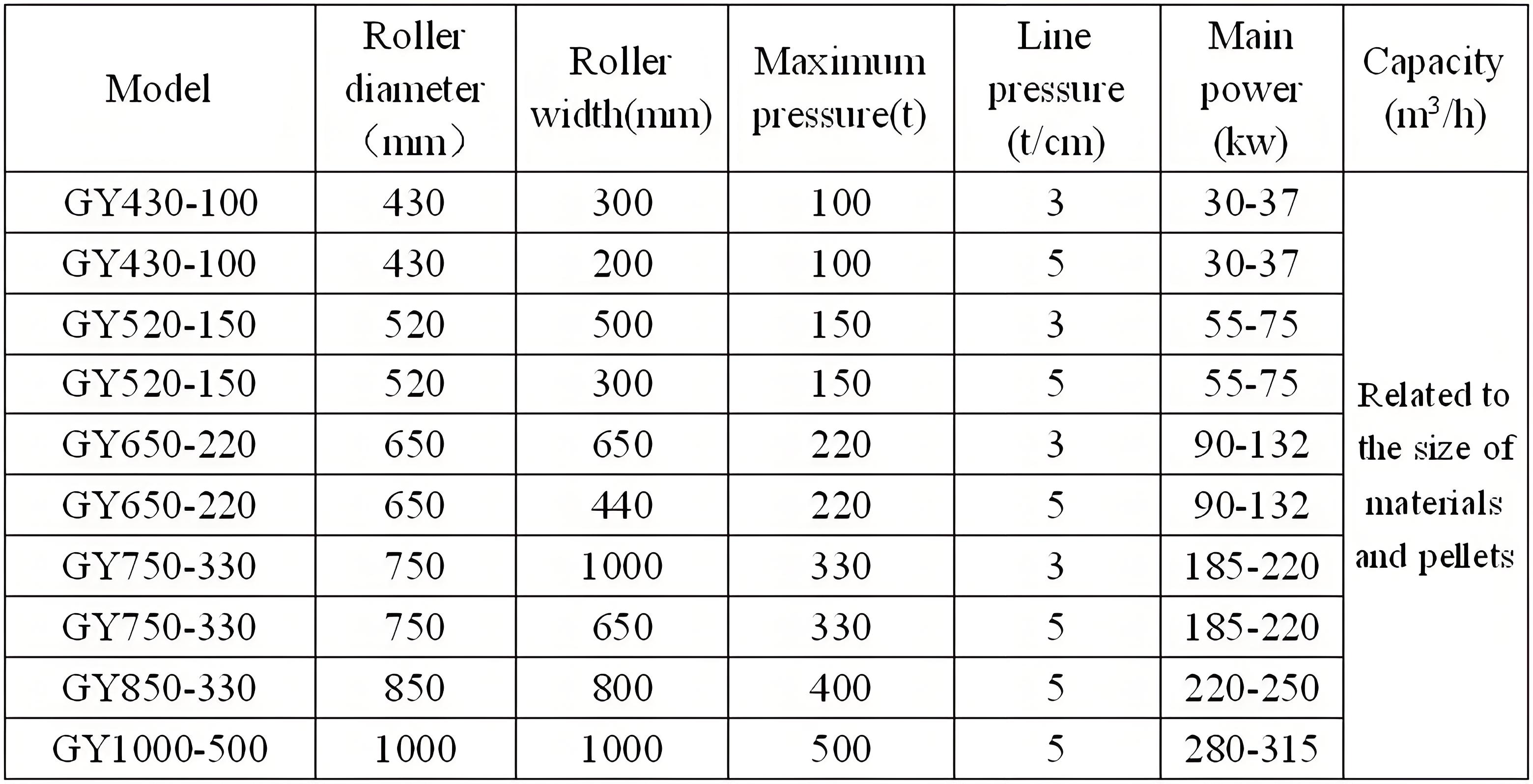

The line pressure from 2t/cm to 5t/cm is considered as medium pressure briquetting machine. And the common ones are 3t/cm and 5t/cm.

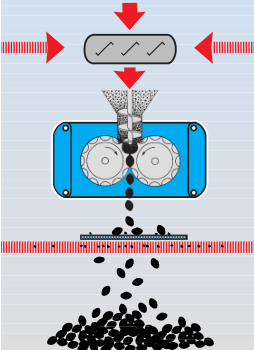

Flipping machine

Flipping machine Vertical

Vertical  Horizontal

Horizontal